糖果 压片糖果检测方法

|

检测项目报价? 解决方案? 检测周期? 样品要求?(不接受个人委托) |

点 击 解 答  |

本文主要介绍了关于糖果 压片糖果的相关检测方法,检测方法仅供参考,如果您想针对自己的样品定制试验方案,可以咨询我们在线工程师为您服务。

1. SENSORY TESTING: This method involves evaluating the appearance, texture, and flavor of the candy to ensure it meets quality standards.

2. CHEMICAL ANALYSIS: Chemical analysis can be used to identify the composition of the candy, including ingredients and any additives present.

3. MICROBIOLOGICAL TESTING: Microbiological testing is important to check for the presence of harmful bacteria or other microorganisms in the candy.

4. MOISTURE CONTENT ANALYSIS: Measuring the moisture content of the candy is crucial to ensure its stability and quality.

5. SHELF LIFE TESTING: Shelf life testing involves storing the candy under various conditions to determine its durability and expiration date.

6. ALLERGEN TESTING: Allergen testing is necessary to detect the presence of any allergens in the candy that could pose a risk to consumers.

7. TEXTURE ANALYSIS: Texture analysis helps determine the hardness, chewiness, and overall mouthfeel of the candy.

8. COLOR ANALYSIS: Color analysis is used to ensure the candy has the correct appearance and color consistency.

9. SIZE AND SHAPE INSPECTION: Checking the size and shape of the candy is important to ensure uniformity and quality control.

10. PACKAGING INTEGRITY TESTING: Packaging integrity testing ensures that the candy is properly sealed and protected from external contamination.

11. FATTY ACID PROFILE ANALYSIS: This analysis helps in determining the types and amounts of fatty acids present in the candy.

12. VISCOSITY TESTING: Viscosity testing measures the flow behavior of the candy, which is important for consistency and quality evaluation.

13. X-RAY INSPECTION: X-ray inspection can be used to detect any foreign objects or contaminants in the candy.

14. SUGAR CONTENT ANALYSIS: Determining the sugar content of the candy is essential for nutritional labeling and quality control.

15. PARTICLE SIZE ANALYSIS: Particle size analysis helps characterize the distribution of particles in the candy for quality assessment.

16. FOREIGN MATERIAL DETECTION: This method involves screening the candy for any foreign materials or contaminants that may be present.

17. SENSORY PROFILING: Sensory profiling involves trained panels evaluating the sensory attributes of the candy to assess its quality.

18. RHEOLOGICAL TESTING: Rheological testing measures the flow and deformation of the candy under applied forces for quality control.

19. ACIDITY TESTING: Acidity testing determines the acidity level of the candy, which can affect its taste and shelf life.

20. DYE ANALYSIS: Dye analysis is used to detect any artificial colors or dyes present in the candy.

荣誉资质

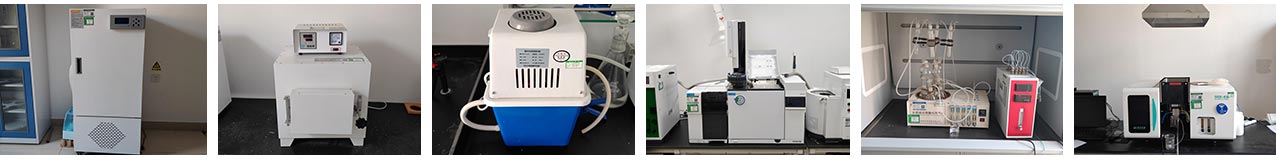

北检院部分仪器展示